#4 Finish

For Stainless Steel Material Selection, See Stainless Steel Alloys

Abraded Finish Options:

| Type of Damage: | Visible Scratches | Visible Marring | Visible Fingerprints | Visible Dust & Dirt | Difficulty to Repair Finish | General Maintenance | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Damage Potential: | L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | L | M | H |

| #4 Grained | ||||||||||||||||||

| Non-Directional | ||||||||||||||||||

| #8 Mirror Polished | ||||||||||||||||||

| Random Swirl | ||||||||||||||||||

| Angel Hair | ||||||||||||||||||

| Bead Blasted | ||||||||||||||||||

L - Least damage potential; Least difficult to repair, requires little maintenance

M - Moderate damage potential; Moderately difficult to repair, requires moderate maintenance

H - High damage potential; Difficult to repair, requires high maintenance

Best choice in terms of performance

Best choice in terms of performance

NOTES:

1. Uniformly abraded and polished finishes are more prone to showing scratches, especially when perpendicular to the grain. Complete re-graining of the entire surface may be necessary in extreme situations.

2. For care and maintenance of stainless surfaces, see:

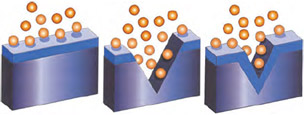

The chromium in stainless steel alloys forms a thin, transparent "passive layer" on the surface of the metal. Although this protective layer is only a few atoms thick, it seals the stainless steel below from the environment. In the presence of oxygen from air or water, it instantaneously reforms if it is damaged. The passive layer is the reason why stainless steel does not require any coating or other form of external corrosion protection.